The

Supply

Chain

Challenge

Global supply chains are complex networks that span

continents, involving countless stakeholders,

processes, and variables. This intricate web is

susceptible to a myriad of disruptions – from natural

disasters and geopolitical tensions to sudden shifts

in consumer demand and unexpected shortages of raw

materials. The COVID-19 pandemic laid bare the

fragility of our supply chains, causing unprecedented

disruptions that reverberated across industries.

Companies scrambled to adapt, and many found

themselves caught off guard, unable to meet customer

demands or maintain operational efficiency. But even

before the pandemic, supply chain disruptions were a

significant concern. According to a study by Deloitte,

79% of organizations with superior supply chain

capabilities achieve revenue growth significantly

above their industry average. This statistic

underscores the critical importance of robust,

resilient supply chains in today's business landscape.

The challenge, then, is clear: How can businesses

predict and prevent supply chain disruptions before

they occur? How can they build resilience into their

operations to weather any storm that comes their way?

The answer lies in the transformative power of

artificial intelligence.

AI

Rises

to

the

Occasion

Artificial Intelligence (AI) is revolutionizing

supply chain management, offering unprecedented

capabilities in prediction, optimization, and risk

mitigation. By leveraging vast amounts of data and

employing sophisticated algorithms, AI can identify

patterns, forecast trends, and detect anomalies that

would be impossible for humans to discern. One of the

key strengths of AI in supply chain management is its

ability to process and analyze data from a wide

variety of sources in real-time. This includes

internal data from ERP systems, IoT sensors, and

inventory management tools, as well as external data

such as weather reports, news feeds, social media

trends, and economic indicators. By synthesizing this

diverse data, AI can create a holistic view of the

supply chain, enabling businesses to: 1. Predict

demand with greater accuracy: AI algorithms can

analyze historical sales data, current market trends,

and even factors like social media sentiment to

forecast demand more precisely. This helps companies

optimize inventory levels, reducing both stockouts and

excess inventory. 2. Identify potential disruptions

early: By continuously monitoring global events,

weather patterns, and other relevant factors, AI can

flag potential risks before they escalate into

full-blown crises. 3. Optimize routing and logistics:

AI can dynamically adjust shipping routes and modes

based on real-time data, ensuring the most efficient

and cost-effective transportation of goods. 4. Enhance

supplier management: AI can assess supplier

performance, predict potential issues, and even

suggest alternative suppliers when risks are detected.

5. Improve decision-making: By providing real-time

insights and running complex simulations, AI empowers

supply chain managers to make more informed decisions

quickly. The impact of AI on supply chain resilience

is significant. A study by McKinsey found that

companies that have adopted AI in their supply chain

operations have reduced forecasting errors by 20-50%

and lost sales due to product unavailability by up to

65%.

Real‑World

AI

Success

Stories

The power of AI in fortifying supply chains isn't

just theoretical. Many companies have already

leveraged this technology to stay ahead of major

supply chain crises. Let's explore some real-world

examples: 1. Procter & Gamble's Control Tower: P&G, a

global consumer goods giant, implemented an AI-powered

'Control Tower' system to manage its vast supply

chain. This system integrates data from various

sources, including weather reports, local news, and

social media, to predict potential disruptions. During

Hurricane Irma in 2017, the Control Tower alerted P&G

to the impending storm's potential impact on its

Florida operations. The company was able to reroute

shipments and adjust production schedules in advance,

minimizing disruptions and ensuring product

availability. 2. Merck's Supply Chain Risk Management:

Pharmaceutical company Merck faced a significant

challenge when a cyberattack disrupted its global

operations in 2017. In response, the company developed

an AI-driven supply chain risk management system. This

system continuously monitors for potential risks, from

cyber threats to natural disasters, and suggests

mitigation strategies. It has enabled Merck to respond

more quickly to disruptions and maintain a more

resilient supply chain. 3. Walmart's Inventory

Management: Walmart has long been at the forefront of

supply chain innovation. The retail giant uses AI to

optimize its inventory management, ensuring products

are in stock when and where they're needed. During the

early stages of the COVID-19 pandemic, Walmart's AI

system detected unusual buying patterns for certain

products. This early warning allowed the company to

quickly adjust its supply chain, increasing stock of

high-demand items and preventing widespread shortages.

4. Amazon's Predictive Shipping: Amazon's

'anticipatory shipping' model uses AI to predict what

customers will buy before they even place an order. By

analyzing past purchases, search queries, and even

cursor hovering patterns, Amazon's AI can forecast

demand with remarkable accuracy. This system allowed

Amazon to navigate the surge in online shopping during

the pandemic more effectively than many of its

competitors, maintaining high levels of product

availability and customer satisfaction. 5. Unilever's

End-to-End Supply Chain Visibility: Unilever

implemented an AI-powered platform that provides

end-to-end visibility across its supply chain. This

system integrates data from multiple sources,

including weather forecasts, crop yields, and consumer

behavior patterns. During the pandemic, this

visibility allowed Unilever to quickly identify

potential shortages and bottlenecks. The company was

able to reallocate resources, adjust production

schedules, and even temporarily streamline its product

range to focus on high-demand items, ensuring

continued supply of essential products. These success

stories demonstrate the tangible benefits of AI in

supply chain management. By leveraging AI, these

companies were able to anticipate disruptions, respond

quickly to changing conditions, and maintain

operational stability in the face of significant

challenges.

Implementing

AI

in

Supply

Chains

While the benefits of AI in supply chain management

are clear, implementing this technology can be a

complex process. It requires a strategic approach, the

right infrastructure, and often, a shift in

organizational culture. Here are some key

considerations for companies looking to leverage AI in

their supply chains: 1. Data Quality and Integration:

AI systems are only as good as the data they're fed.

Companies need to ensure they have access to

high-quality, relevant data from across their supply

chain. This often involves integrating data from

multiple systems and external sources, which can be a

significant undertaking. 2. Technology Infrastructure:

Implementing AI requires robust technology

infrastructure. This includes not just the AI

algorithms themselves, but also the systems to

collect, store, and process large amounts of data.

Cloud computing platforms often play a crucial role in

providing the necessary computational power. 3.

Skilled Personnel: Successful AI implementation

requires personnel with the right skills. This

includes data scientists who can develop and refine AI

models, as well as supply chain professionals who

understand how to interpret and act on the insights

provided by these models. 4. Change Management:

Introducing AI into supply chain operations often

requires changes to existing processes and ways of

working. Effective change management is crucial to

ensure buy-in from all stakeholders and to realize the

full benefits of the technology. 5. Ethical

Considerations: As with any AI implementation, it's

important to consider the ethical implications. This

includes ensuring data privacy, addressing potential

biases in AI models, and considering the impact on

workforce roles. 6. Continuous Improvement: AI systems

aren't a 'set it and forget it' solution. They require

ongoing monitoring, refinement, and updating to ensure

they continue to provide accurate and relevant

insights as conditions change. Despite these

challenges, the potential benefits of AI in supply

chain management make it a worthwhile investment for

many companies. As the technology continues to evolve

and mature, we can expect to see even more innovative

applications in the future.

The

Future

of

AI

in

Supply

Chains

As we look to the future, the role of AI in supply

chain management is set to become even more prominent.

Here are some trends and developments we can expect to

see: 1. Increased Automation: AI will enable greater

automation across the supply chain, from robotic

process automation in administrative tasks to

autonomous vehicles in logistics. This will lead to

increased efficiency and reduced human error. 2.

Enhanced Predictive Capabilities: As AI models become

more sophisticated and have access to more data, their

predictive capabilities will improve. This will allow

for even more accurate demand forecasting and risk

prediction. 3. Blockchain Integration: The combination

of AI and blockchain technology has the potential to

revolutionize supply chain transparency and

traceability. AI can analyze blockchain data to detect

anomalies and ensure compliance across the supply

chain. 4. Sustainability Optimization: AI will play a

crucial role in helping companies optimize their

supply chains for sustainability. This includes

reducing waste, optimizing transportation routes for

lower emissions, and ensuring ethical sourcing

practices. 5. Cognitive Supply Chains: The concept of

'cognitive' supply chains – those that can learn,

adapt, and make decisions autonomously – will become a

reality. These AI-driven supply chains will be able to

self-optimize and self-heal, responding to disruptions

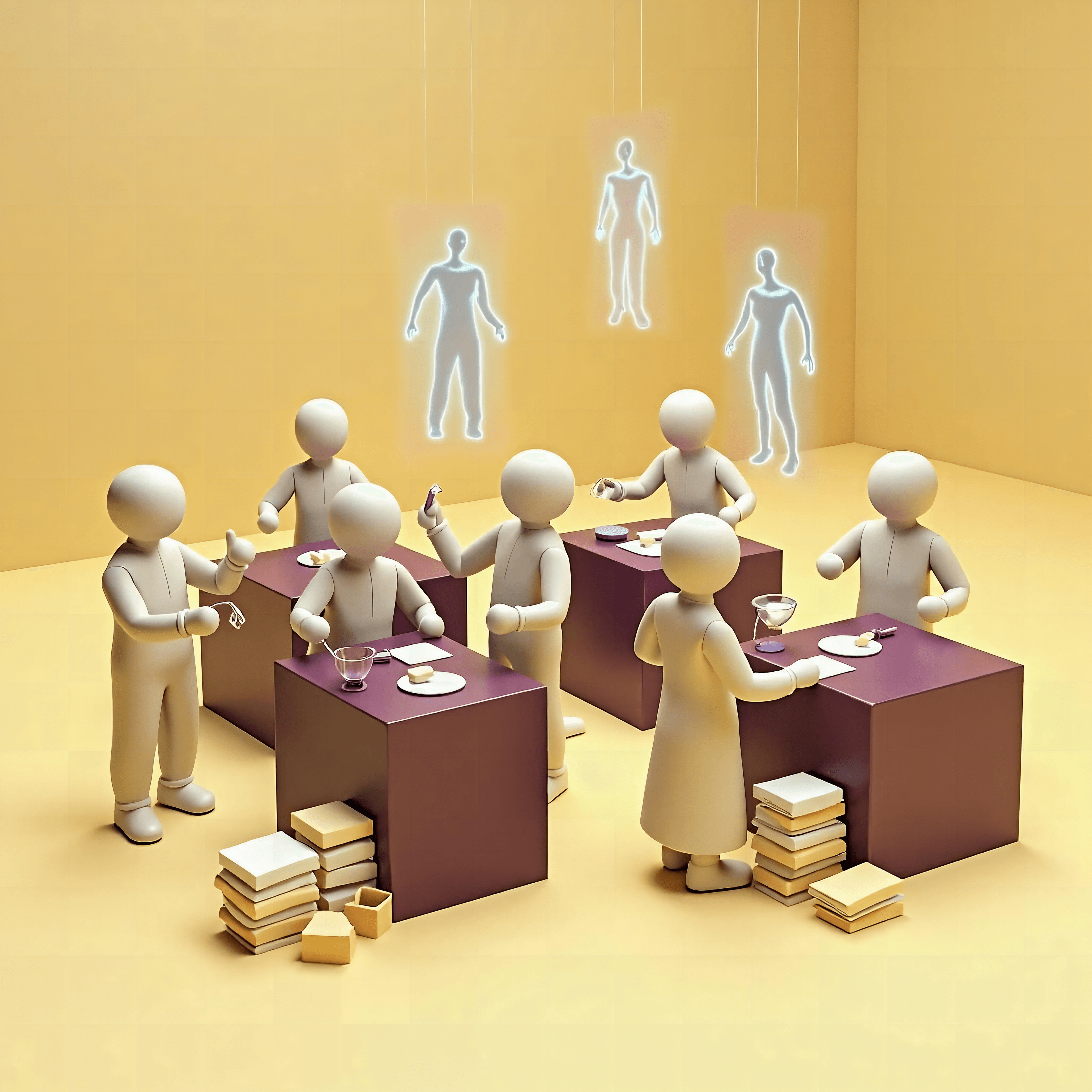

with minimal human intervention. 6. Human-AI

Collaboration: Rather than replacing human workers, AI

will increasingly augment human capabilities in supply

chain management. We'll see more collaborative

intelligence, where AI systems work alongside human

experts to make complex decisions. 7. Edge Computing:

The rise of edge computing will allow AI processing to

occur closer to the source of data generation. This

will enable faster real-time decision making in areas

like inventory management and logistics. As these

trends unfold, the ability to effectively leverage AI

in supply chain management will become a key

competitive differentiator. Companies that can harness

the power of AI to create more resilient, efficient,

and responsive supply chains will be better positioned

to thrive in an increasingly complex and uncertain

business environment.

How

Zue

Can

Help

At Zue, we understand the immense potential of AI in

revolutionizing supply chain management. We also

recognize the challenges that companies face in

implementing and leveraging this technology

effectively. That's where our expertise comes in. Zue

specializes in developing custom AI solutions tailored

to the unique needs of each business. Our team of

experienced data scientists, AI engineers, and supply

chain experts work collaboratively to create AI

systems that can truly transform your supply chain

operations. Here's how Zue can help your company

harness the power of AI: 1. Comprehensive Supply Chain

Assessment: We begin by conducting a thorough

assessment of your current supply chain operations.

This helps us identify areas where AI can have the

most significant impact, whether it's demand

forecasting, risk management, or logistics

optimization. 2. Custom AI Solution Development: Based

on our assessment, we develop a custom AI solution

tailored to your specific needs. This could involve

creating predictive models for demand forecasting,

developing risk assessment algorithms, or designing

optimization tools for inventory management. 3. Data

Integration and Management: We help you integrate data

from various sources across your supply chain,

ensuring that your AI systems have access to

high-quality, relevant data. Our team can also assist

in setting up the necessary data management

infrastructure to support your AI operations. 4.

Implementation and Training: We don't just develop the

AI solution – we work closely with your team to

implement it effectively. This includes training your

staff on how to use and interpret the AI insights,

ensuring that you can derive maximum value from the

technology. 5. Continuous Improvement and Support: Our

relationship doesn't end with implementation. We

provide ongoing support and continuously refine and

update your AI systems to ensure they remain effective

as your business evolves and market conditions change.

6. Ethical AI Practices: At Zue, we're committed to

ethical AI development. We ensure that all our AI

solutions are developed and implemented with proper

consideration for data privacy, fairness, and

transparency. 7. Scalable Solutions: Whether you're a

mid-sized company looking to optimize your regional

supply chain or a multinational corporation managing a

global network, our solutions are designed to scale

with your needs. By partnering with Zue, you're not

just getting an AI solution – you're gaining a

strategic partner committed to helping you build a

more resilient, efficient, and intelligent supply

chain. In today's volatile business environment,

having a robust, AI-powered supply chain isn't just an

advantage – it's a necessity. With Zue's expertise,

you can stay ahead of disruptions, optimize your

operations, and turn your supply chain into a true

competitive differentiator. Don't let supply chain

disruptions hold your business back. Let Zue help you

harness the power of AI to weather any storm and

emerge stronger on the other side. Together, we can

build a supply chain that's not just resilient, but

truly intelligent – ready to adapt, evolve, and thrive

in the face of any challenge.

Embracing

the

AI

Revolution

As we've explored throughout this post, AI is not

just transforming supply chain management – it's

revolutionizing it. From predicting disruptions before

they occur to optimizing operations in real-time, AI

is providing businesses with capabilities that were

once thought impossible. The companies that have

already embraced this technology are reaping

significant benefits. They're able to respond more

quickly to disruptions, optimize their operations for

greater efficiency, and provide better service to

their customers. In an era where supply chain

resilience can make or break a business, these

advantages are invaluable. But the AI revolution in

supply chain management is still in its early stages.

As the technology continues to evolve and mature, we

can expect to see even more innovative applications

and transformative impacts. The supply chains of the

future will be cognitive, self-optimizing networks

that can adapt to changing conditions with minimal

human intervention. However, it's important to

remember that AI is not a magic solution. Its

effectiveness depends on how well it's implemented and

integrated into existing processes. It requires

quality data, the right infrastructure, skilled

personnel, and a culture that's open to change and

innovation. Moreover, as we increasingly rely on AI

for critical business decisions, we must also grapple

with important ethical considerations. How do we

ensure that AI systems are fair and unbiased? How do

we maintain transparency in AI-driven decision-making?

How do we balance the benefits of automation with the

need to support and retrain displaced workers? These

are complex questions that don't have easy answers.

But they're questions that businesses must engage with

as they navigate the AI revolution. Despite these

challenges, the potential benefits of AI in supply

chain management are too significant to ignore. In an

increasingly complex and uncertain business

environment, AI offers a powerful tool for building

more resilient, efficient, and responsive supply

chains. For businesses looking to stay competitive in

the years to come, embracing AI in supply chain

management isn't just an option – it's an imperative.

Those who successfully leverage this technology will

be better positioned to weather future storms,

capitalize on new opportunities, and deliver value to

their customers and stakeholders. The future of supply

chain management is intelligent, adaptive, and

resilient. And that future is being built with AI. Are

you ready to be part of this revolution? Remember, you

don't have to navigate this journey alone. With

partners like Zue, you can access the expertise and

support you need to successfully implement AI in your

supply chain operations. Together, we can build supply

chains that aren't just prepared for the future –

they're shaping it. So, as you consider the future of

your supply chain, ask yourself: Are you ready to

weather the next storm? Are you prepared to seize the

opportunities that lie ahead? With AI, you can be. The

time to act is now. Don't let the future catch you

unprepared. Embrace the AI revolution in supply chain

management, and position your business for success in

the years to come.